Developing And Managing An Effective Change Control Program

Regulatory agencies require pharmaceutical and medical device companies to have a systematic approach to managing all changes made to a facility, its product, or a quality system. Given the fact that changes are inevitable, it is essential that companies have a compliant and effective change control program to ensure that no unnecessary or cGMP non-compliant changes occur. This Change Control training course will discuss regulatory expectations from the FDA, EU, and ICH perspectives, review all the required components of a thorough Change Control program; as well as, and discuss the elements regarding the successful management of an effective Change Control system.

Topic 1: Regulatory Guidance Review

- FDA (CFR)

- EU (EurdraLex)

- ICH Q10

Topic 2: Review all Elements of a Change Control Record

- Discuss the importance of utilizing Subject Matter Experts from multiple functional areas to ensure proper evaluation, approval, and implementation of proposed changes

- Ensure changes do not negatively impact the business or established marketing authorization

- How to incorporate a Quality risk-based approach to evaluating proposed changes

- Ensure changes are implemented in a timely manner by effective use of the Change Control Review Board (CCRB) and Quality Metrics

- Understand what steps should be taken post-implementation to confirm the objectives were achieved

Course Objectives: At the completion of this course, attendees will be able to:

- Interpret the requirements of the FDA, EU, and ICH guidelines regarding compliant Change Control records

- Understand all the required components of a thorough Change Control record

- Understand all the elements of effective Change Control management:

- How to develop a cross-functional team to ensure proper evaluation, approval, and implementation of proposed changes

- Ensure changes do not negatively impact the business or established marketing authorization.

- How to incorporate a Quality risk-based approach to evaluating proposed changes

- Ensure changes are implemented in a timely manner by effective use of the Change Control Review Board (CCRB) and Quality Metrics

- Understand what steps should be taken post-implementation to confirm the objectives were achieved

Operations employees that participate in Manufacturing, Engineering, Validation, Quality Assurance, and Regulatory Affairs as part of their job function – include employees in the following departments:

- Production

- Engineering and Validation

- Facilities / Maintenance

- Quality Assurance

- Regulatory Affairs

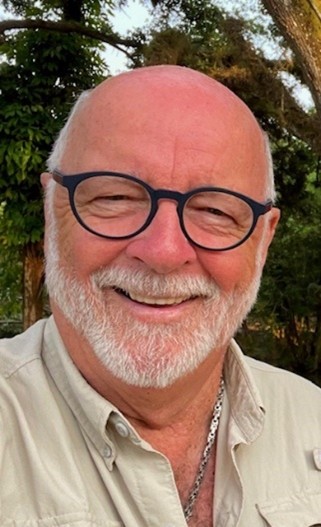

Ms. Thomas has over two decades of cGMP hands-on industry experience in both pharmaceutical and medical device manufacturing operations. Her experience covers all Quality Systems; as well as, all areas of validation; including, process/product validation, facilities validation, CSV and 21 CFR Part 11, test method validation, equipment/automated processes and cleaning validation.

Utilizing strategic thinking, risk based approaches, and Lean principles, she has demonstrated success in steering and managing complex projects within the pharmaceutical and medical device industries.

Upcoming Webinars