Reshore Production

Manufacturing is the backbone of national affluence, prosperity, and military power. Loss or absence of manufacturing capability has been a universal leading indicator of national decline; there have been no exceptions. While manufacturing supremacy played a central role in American victory in the Second World War, we have unwisely ceded a good part of our manufacturing base to other countries including the People's Republic of China; a dangerous geopolitical rival that has threatened its neighbors and also the United States itself with war. The PRC meanwhile has a long track record of selling us counterfeit and substandard items (including heparin and N-95 respirators) that have put human life at risk, and it threatened to cut off medical exports to the United States during the Covid-19 epidemic.

The Federal debt is (as of June 2023) $31.5 trillion or almost $100,000 for every American including children and retirees. The only way to get out of this debt is to produce our way out, which requires a near-doubling of the gross domestic product (GDP) growth rate. Industrialists such as Henry Ford, Frederick Winslow Taylor, Frank Gilbreth, and Harrington Emerson proved more than a hundred years ago that this can be done; the Ford Motor Company made the United States the wealthiest and most powerful nation on earth.

1. Manufacturing is the foundation of national prosperity and also military power. The exchange of raw materials or, even worse, borrowed money, for manufactured goods, is the relationship between a colony and its colonial master.

2. A decline in manufacturing capability is a universal leading indicator of a decline in national well-being and affluence. There have been no exceptions.

- Spain's and Portugal's discovery of treasure in the New World ruined these countries for centuries by encouraging them to purchase manufactured goods from their rivals, England and Holland. The result was that England and Holland ended up with most of the gold and silver as well as the manufacturing base. England even bought the vineyards of Oporto (the source of Port wine) with Portugal's own money, which it had exchanged for manufactured goods. The People's Republic of China is similarly buying up property in the United States, with often-borrowed money we exchanged to it for manufactured goods.

- Manufacturing superiority played a decisive role in Union victory in the American Civil War, and Allied victory in the Second World War when the United States outproduced all the other belligerents put together.

3. It is bad to cede this power to Mainland China, an unreliable supplier and a dangerous geopolitical rival. The PRC has threatened the United States, Taiwan, Japan, the Philippines, and other countries, and is using the manufacturing capability we ceded to it to build large quantities of weapons. The PRC also has a long record of intellectual property theft and the intentional sale of counterfeit and substandard products.

4. A manufacturing resurgence is the only way to reverse the Federal deficit.

- Reshoring and productivity improvements can deliver a 10 percent or more growth rate in the GDP, but we must first drop the ruinous paradigm that cheap labor delivers low prices and high profits. It is often symptomatic of the opposite: high prices and low profits.

- The good news is that proven, off-the-shelf solutions to the challenge of cheap offshore labor have been available for more than 100 years. Henry Ford and his contemporaries proved that these methods, which only later became known as the Toyota production system, deliver world-class bottom-line results.

All we need to do is abandon the dysfunctional paradigm that cheap labor is somehow desirable, and realize instead that cheap labor is often symptomatic of high prices and low profits. This is because it gives enormous amounts of waste a place to hide. The next step is to put to work the easily understandable principles that Ford and his contemporaries taught us long ago and proved to work with bottom-line results.

These methods were in fact developed partly in response to not only the menace of cheap offshore labor in the early twentieth century but also to competition from organizational methods that Japan adopted from Prussia in the nineteenth century. It was recognized at the time that the struggle would be one of efficiency against inefficiency, with high-wage labor playing a central role in the former, and nothing has happened since then to change this.

All people with responsibility for strategic decision-making including supply chain. Manufacturing managers and professionals will also find the techniques discussed in the last part of the webinar useful.

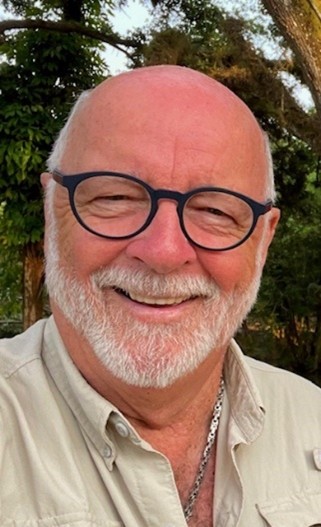

William A. Levinson, P.E., is the principal of Levinson Productivity Systems, P.C. He is an ASQ Fellow, Certified Quality Engineer, Quality Auditor, Quality Manager, Reliability Engineer, and Six Sigma Black Belt. He is also the author of several books on quality, productivity, and management, of which the most recent is The Expanded and Annotated My Life and Work: Henry Ford’s Universal Code for World-Class Success.

Upcoming Webinars